Homepage / High-tech machining & processes

High-tech machining & processes

Machining solutions for technical and high-precision parts

- Because the performance of your mechanisms depends on the precision of their components, the engineers and technicians at the HBP group support you in the industrialization and production of complex parts from all types of materials.

- In-depth study of the tool-material pairing to determine the best machining strategies

- Optimization of the machining process to complete all parts in a single phase

- Able to meet all your requirements, from prototyping to the manufacture of millions of parts.

- Over 1,000 tonnes of material machined per year

Concrete solutions to bring your ideas to life

A unique process for burr-free cross-drilling

To meet the extreme requirements of hydraulic components: zero burr, perfect sealing and very tight surface tolerances, the HBP group has developed a unique in-line deburring process. Designed by our R&D department, this integrated system makes it possible to produce transverse bores of less than 0.15 mm without additional reworking, guaranteeing quality, reliability and cost control.

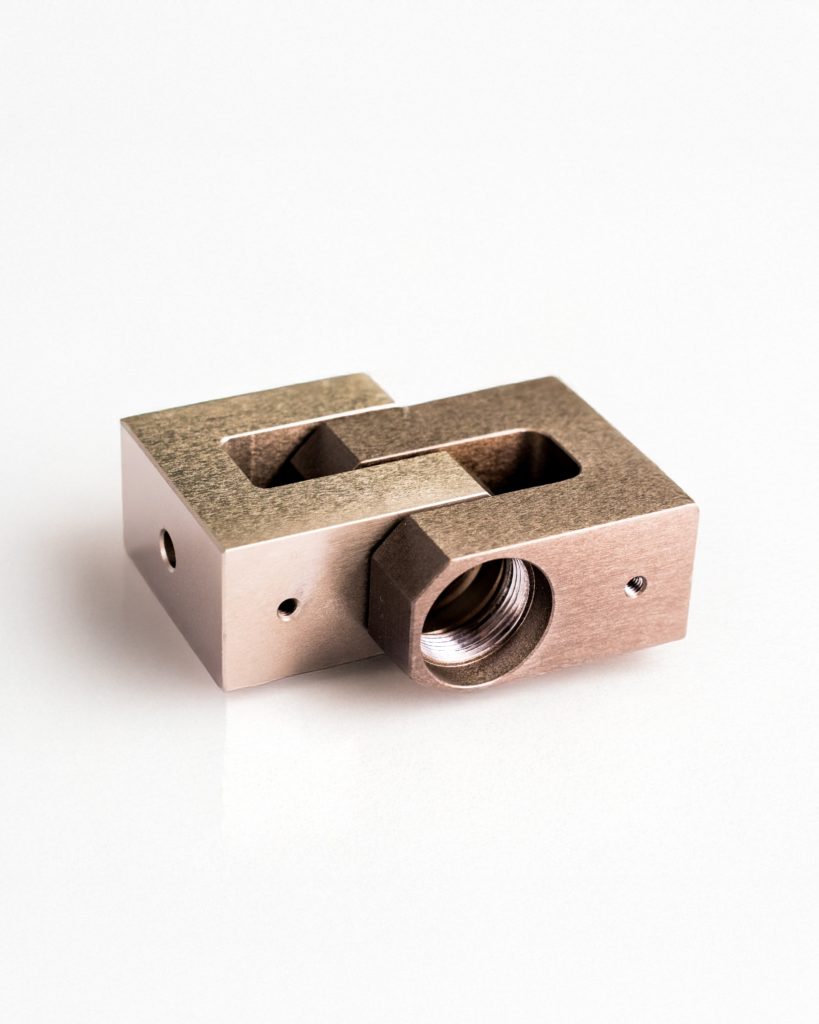

Custom machining of prismatic parts

Traditionally, bar turning machines use bar stock to produce cylindrical parts. Thanks to the development of 5-axis turning-milling centers, we are now able to produce prismatic parts with complex shapes, far removed from conventional geometries.

Production and Assembly of Sub-Assemblies

At the HBP group, we also manufacture sub-assemblies, where mechanical parts are assembled to form a functional whole. This process makes it possible to control the entire system, offering not only maximum quality and reliability for each sub-assembly, but also an economically advantageous solution.

Our teams, their experience, their technical expertise and the customization of our processes enable us today to bring real added value to our customers by providing them technically and economically optimized solutions.

Questions about our expertise?

Do you have a technical challenge to submit?