Three strategic businesses to create the industry of tomorrow

High-tech machining & proceses

Because the performance of your mechanisms depends on the precision of their components, The engineers and technicians at the HBP group can support you throughout the design, industrialization and production of complex parts from all types of materials. Implementing the best machining strategy requires an in-depth study of the tool-material pairing and machining strategies designed to produce the part in a single phase. With over 1,000 tonnes of material machined per year, we can meet all your requirements, from prototyping to the production of millions of parts.

Ceramics & new materials

Drawing on our expertise across the entire production chain for ceramic parts, we bring your ideas to life by designing tailor-made solutions based on formulations developed in-house. This enables us to develop ceramics with specific properties and in a variety of colors, according to your specifications. Our mastery of sintering and coloring techniques guarantees the highest level of finish for all your parts. Always on the lookout for new solutions to offer you, our R&D department is constantly monitoring and researching new materials, particularly bio-sourced ones or those derived from recycling.

Fastening solutions

Our engineers and technicians put all their expertise into the design and industrialization of innovative fasteners. We strive to deliver the most appropriate solutions with the optimal balance between technical performance and cost efficiency. We devellop inserts and screws for plastics, composites, honeycomb panels and sandwich panels and light alloys, to connect your parts reliably, safely, and precisely. This same level of standards apply to our catalog references, with rigorous attention to standardization and conformity throughout the production process.

Concrete solutions to bring your ideas to life

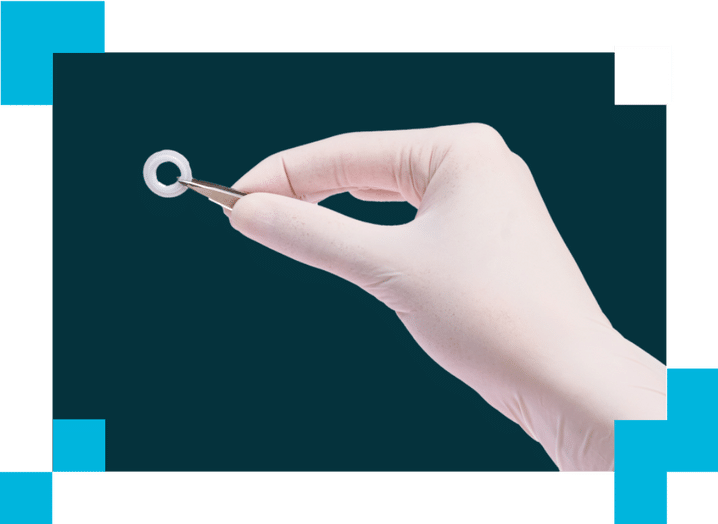

Punchi® : An Innovation in Ceramic Machining

The HBP group is revolutionizing ceramic machining with Punchi®, an innovative and eco-responsible in-house process that enables the entire process to be controlled: from the formulation of ceramic powders to finishing after sintering, the group offers high-precision ceramic parts.

With a process three to four times more competitive than existing ones, and which reincorporates its own machining waste, the HBP group provides innovative solutions in the field of technical ceramics, and beyond.

Production and Assembly of Sub-Assemblies

At the HBP group, we also manufacture sub-assemblies, where mechanical parts are assembled to form a functional whole. This process makes it possible to control the entire system, offering not only maximum quality and reliability for each sub-assembly, but also an economically advantageous solution.

Custom fasteners: Mastery of Combined Processes

With over 50 years’ experience, SECAM develops fastening solutions tailored to your specific needs. By combining cold forming, machining, injection or overmolding, we offer high-performance, cost-effective technical fasteners. Our strength: transforming a standard into a customized solution through intelligent re-engineering.

The HBP team

"La Cordée"

This unique structure was created within our group to support all our initiatives in favor of cohesion, inclusiveness and sharing. Find out more about our latest collective actions, which contribute to the personal and professional fulfillment of each individual in a respectful, positive and supportive environment.

Any questions about our expertise?

Do you have a technical problem?

Our core values

Here are the three fundamental values that unite us as a group, guide us in every action we take and define the relationships we want to build with our customers.

Innovation

Conviviality

Responsibility